LAROCHE

- Textile waste recycling lines

- Opening and blending lines

- Airlay Nonwoven lines

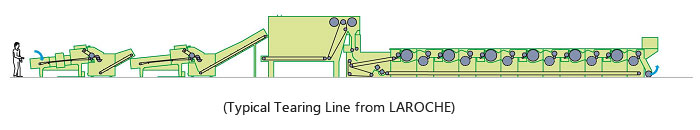

Textile Waste Recycling Lines:

- Laroche Soft Cotton Waste process lines :capacity 40 kgs to 1000 kgs per hour

- Flax Cottonizing Lines :up to 250 kgs per hour per unit

- Textile Soft Waste Recycling Lines: 40 kgs to 1000 kgs waste per hour.

- Textile Hard Waste Recycling Lines The textile waste hard yarn, selvedge waste, cut fabric, chindies in sheeting, shirting, knitting and bottom

- Weight, denim etc can be recycled back into fibres.

LAROCHE Offer 3 models : CADETTE, EXEL & JUMBO. The working width ranges from 500 mm to 2000 mm. The production capacity of these lines ranges from 50 to 1000 kgs fibres of Open End Spinning quality of about 100 kgs to 3000 Kgs for use in Nonwovens.

Fibre Opening and Blending Lines:

for thorough opening and accurate and intimate blending of fibres for spinning units of all fibres, particularly for non-woven lines

Nonwoven Lines:

"Airlay" Mat Forming (Nonwoven) Lines to use all types of fibres – short, re-cycled to long and coarse natural fibres (even glass fibres). This machine produces nonwoven mats from 200 gr/m2 upto 3000/4000/8000 gr/m2 (according to fibres) and for nonwoven width upto 4000 mm.

There are two models:

The AIRLAY with "Flexiloft" system for high loft nonwovens to produce Mattress felts(bedding), furniture, carpet underlay, insulation, automotive, geotextiles.The Airfelt with "Resinfelt" option for semi-cured resinated felts for flat or moulded parts for automotive and appliance industries.

Special Equipments:

Edge Trim Recycling equipments –Minitrim and Minitrim HSP in 200 mm width for lightweight nonwovens with speeds up to 350 m/min. Supertrim in 500 and 1000 mm width and speeds up to 45 m/min with options of unwinding system for rolls, feeding conveyor, water spraying system.

For more details, please visit their website: ( www.laroche.fr)